The motors of pumps and fans represent an important item of energy consumption in the building design.

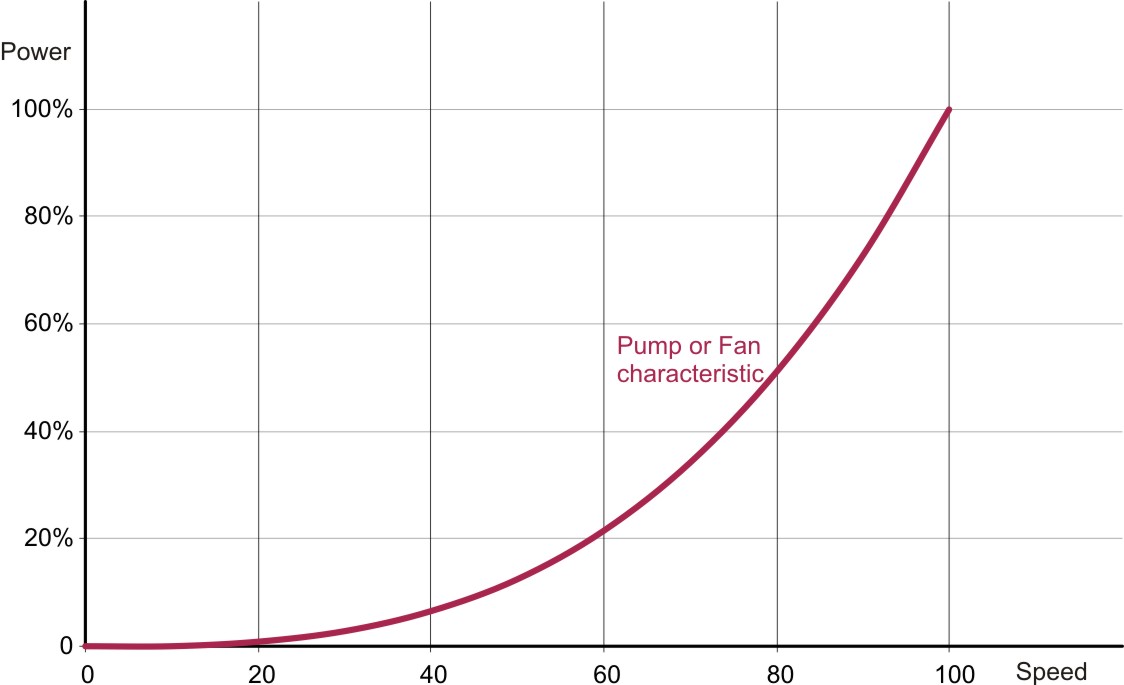

The devices, used mainly for air-conditioning and heating, are most of the time centrifugal and are characterized by a variable power consume according to the cube speed. (See graphic below)

The use of the variable speed drives is not any more to show, their capacity to control the speed of the engines offers substantial profits of energy. A pump for example, needs only 20% of power to run at 60% of its speed.

Beyond these advantages, the variable speed drives offer other possibilities of economies, in particular at the time of the building design and building maintenance.

Building design

The majority of the drives are able to provide information of current, voltage, power and energy (kWh) consumed by the motor, either on local display or remotely by connection on a communication bus.

Extract of the parameters list of a ATV71 (Telemecanique Altivar Variable Speed Drives )

“LCr” motor current

“UOP” motor voltage

“APH”: motor energy consumption in kWh

“UNT” unit, it changes automatically when the value reached the maximum format of the parameter

“OPr”: instantaneous power consumed by the motor in % of the nominal power of the drive

In all the cases where a precise counting is not necessary, it is possible to make the saving in separate sensors.

Extract of the parameters list of a ATV71 (Telemecanique Altivar Variable Speed Drives )

“LCr” motor current

“UOP” motor voltage

“APH”: motor energy consumption in kWh

“UNT” unit, it changes automatically when the value reached the maximum format of the parameter

“OPr”: instantaneous power consumed by the motor in % of the nominal power of the drive

In all the cases where a precise counting is not necessary, it is possible to make the saving in separate sensors.

The yield of a motor is about 95% with its nominal load. It drops when the load decreases because part of these losses is constant: control supply, internal ventilation of the drive. This phenomenon is mainly compensated by the reduction in the losses of commutation which are related to the output current of the drive. Moreover for small drives (few kw), the power consumed by the auxiliaries is perfectly negligible.

Consequently, the power consumed by the motor gives a good indication of total consumption and the precision about a few % is sufficient in the majority of the cases.

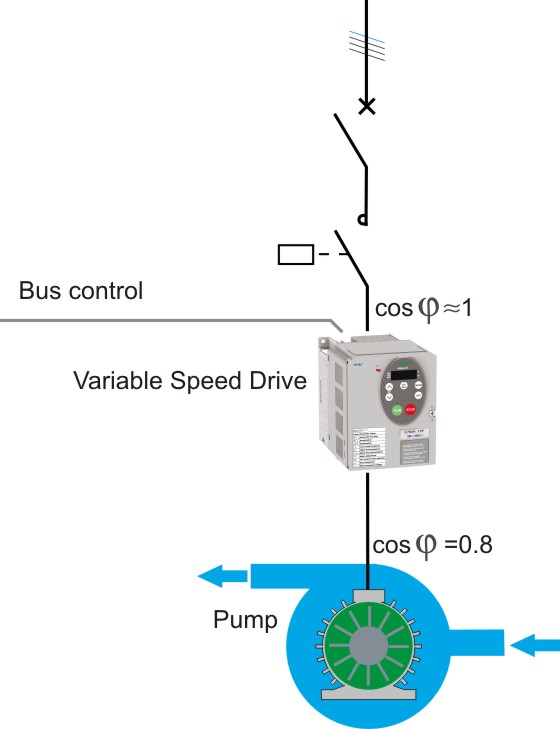

The variable speed drives show another interesting characteristic. It comprises, on the network side, a rectifying bridge followed by condensers filtering which smooth the voltage and correct in more the power-factor. A motor having a cos φ of 0.8 will be seen, upstream the drive, with a cos φ near to 1.

Building maintenance

The fact that the power grows like the cube speed offers interesting possibilities of detection, the measurement of this parameter makes it possible to identify anomalies which would be not very visible by the speed measurement alone.

By supervising the histogram of the power according to time it will be possible to detect a clogging of pump or a clogging of dirtying of ventilation. It will be enough to parameterize a threshold of detection to trip an alarm making it possible to carry out a maintenance action.

http://engineering.electrical-equipment.org/energy-efficiency-motors/cost-effective.html#more-1411

Post a Comment